TWIST 700 – TWIST 300

TWIST 700

A new concept of tilting machine

The TWIST 700 is a pressure forming – punch and die machine with lower tilting platen without mechanical cams. One step ahead technology that makes TWIST 700 the most interesting solution for medium – high productions of tubs, dairy containers, pots, disposable cups and lids that require closed cutting tolerance, high product quality within a fully automated process.

Investment means value:

- New motion system without cams to reach up to 50 cycles/minute in production

- Electric extractor for better cycle synchronization

- Constant quality, high performance and rationalized material utilization

- MLS System (Machine Learning System) for initial self-setting of the cycle parameters

- Higher clamping force insuring more cavities for PET and PP materials

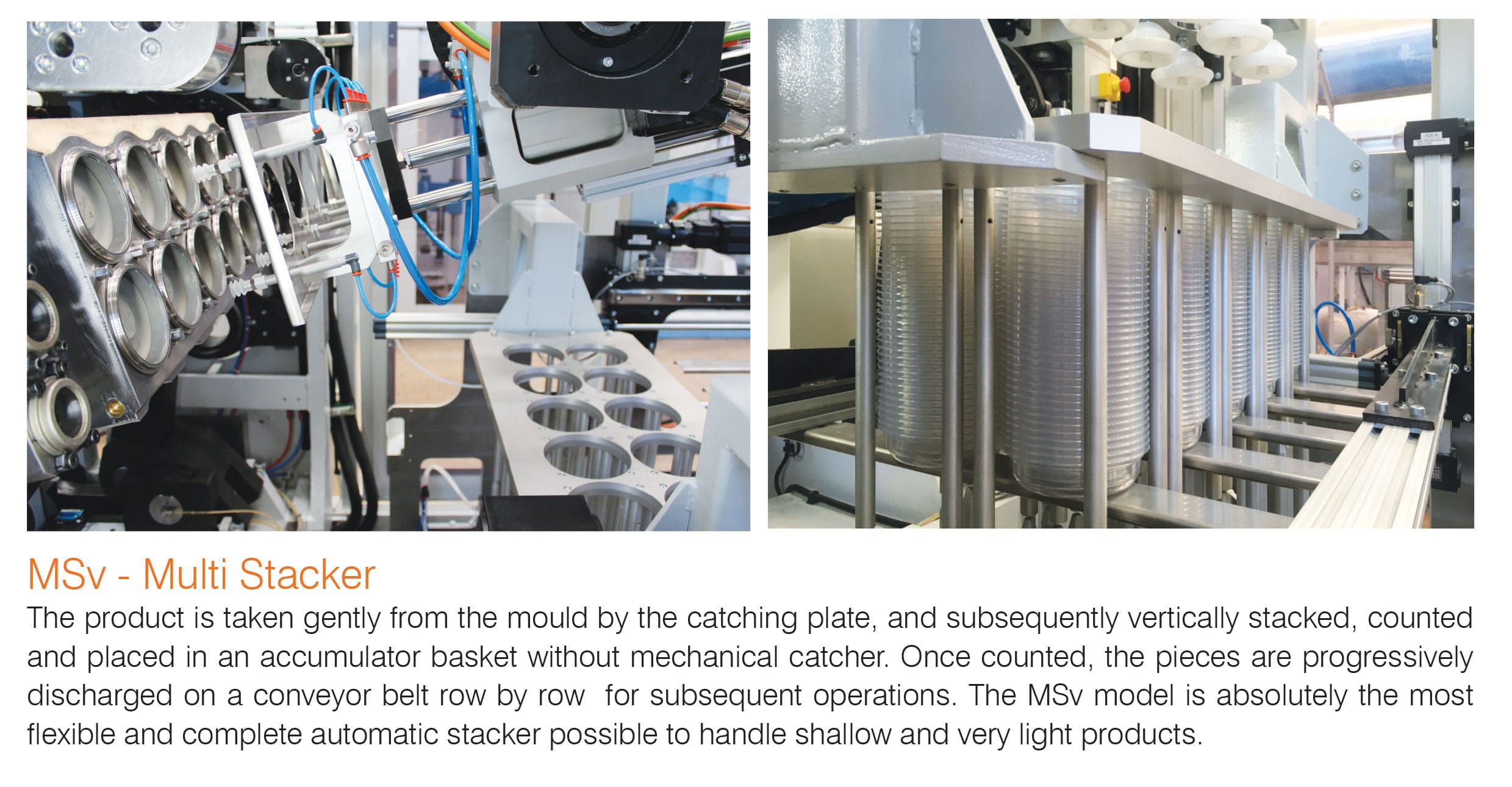

- Universal stacker enables easy automatic handling of light and shallow products to the packaging machine

- Hygienic production as the stacking system is not using any brushes or rubber material

- Integrated cooling system with temperature monitoring to insure a stable and safe process

- Easy operating and maintenance

TWIST 300

Small, simple, flexible, reliable and performing.

The very wide range of applications makes the TWIST 300 the most interesting solution for small productions like batches of tubs, cups and lids. The incomparable quick mould change and the fast setting, together with the very low tools cost, make of the TWIST 300 the ideal machine for new mould tests as well as pre-production sampling.

Main Features:

- Automatic Unwinder

- Brushless motor and inverter for sheet conveying system

- Upper and Lower heating ovens

- Adjustable upper forming platen height

- Lower moving platen with 90 degrees tilting function

- Tilting may be switched off and lower platen can be operated vertically, down and upward

- Pneumatic plugs assist

- Automatic centralized forced lubrication

- Cooling circuit ready for refrigeration plant connection

- Compressed air tank incorporated into the machine