LIVESTREAM OPEN HOUSE

SYNERGIZING TECHNOLOGIES – Fall Edition

60 minutes of exclusive content

October 15th 2021 – 3 sessions available

WHY attend? 4 top reasons:

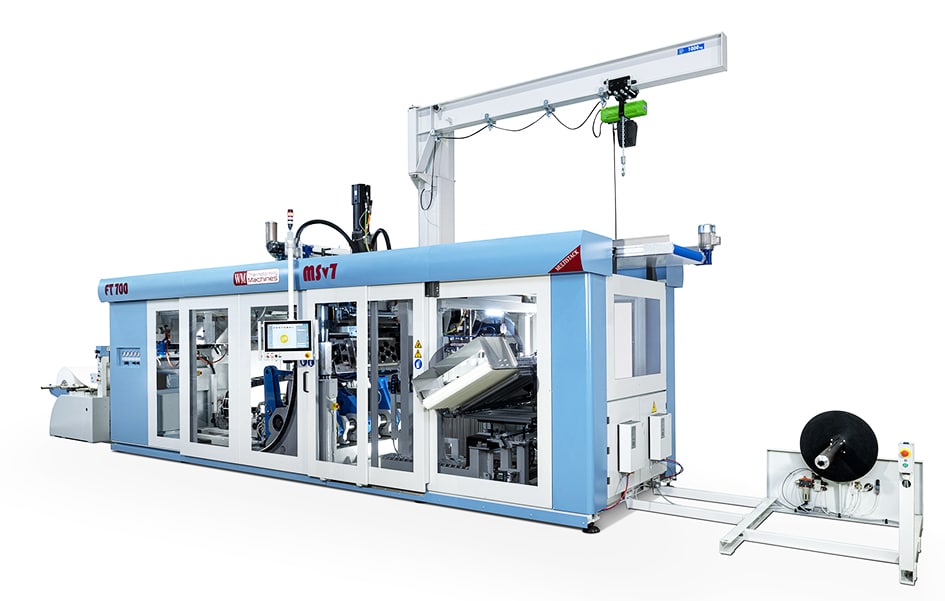

- Know about our tilting bed machine to produce dairy containers with close cutting tolerance

Starring our FT 700 + Msv Stacker: one solution for tubs and lids packed in a fully automated process - Hear about PET expanded material

PET Rigid film VS expanded – Mechanical characteristics VS productivity and cost, on a FC 1000 IM2 steel rule die machine with 16 up tray mold in production - Improve your production efficiency

Learn how to improve the Overall Equipment Efficiency (OEE) with Industry 4.0, using Machine & real production data, analysis and action - Expert advise

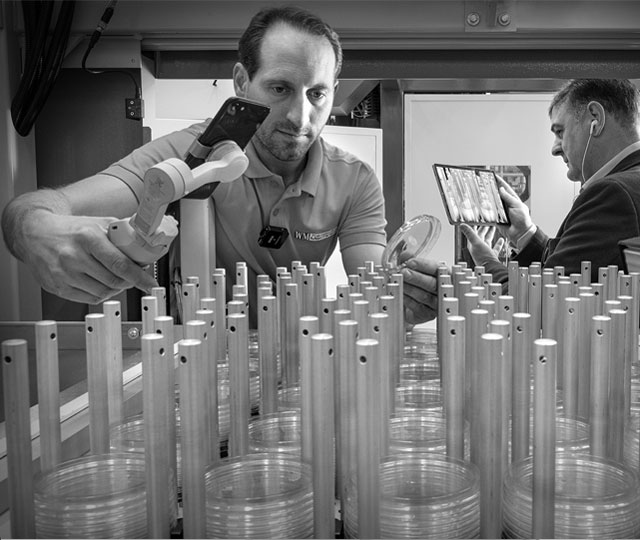

Live consultation available with our experts!

HOW is it done?

- Test run in WM with our FT 700 + MSv Stacker

- Interview with Customer

- Synergy with mold makers and extrusion companies to find the right product/market for XPET

- Turnkey solutions integrating machine data to analyze and improve equipment efficiency (Industry 4.0)

WHAT will you get?

- Livestream private access

- 1-hour professional content

- 2 machines in action: FC 1000 IM2 steel rule die in production LIVE, and video of FT 700 tilting bed machine

- Test report comparison: PET rigid film VS Expanded

- Case study with a real Industry 4.0 project. Let the results inspire your company’s evolution!

- Live Questions & Answers. Ask the expert!

Closed Cutting tolerance, high quality, repeatability, and flexibility for the dairy packaging.

From flat lids to deep draw products all in one machine, with MSv7 multi stacker in action.

4-steps dynamic mold centering to ensure PERFECT CUT and LONGER DIE LIFE.

Enjoy inspiring technology discussions!

AGENDA:

- WM THERMOFORMING MACHINES | Luca Oliverio – Sales Director

Welcome – Why choose WM? - WM THERMOFORMING MACHINES | Gregory Romanski – Sales Area Manager (North & South America)

Event Agenda - WM THERMOFORMING MACHINES | Andrea Crespi – Sales Area Manager (Asia & MEA)

FT 700 Msv7 Yogurt cup: Stacker flexibility and tilting mould perfect cut - Guest Speaker: ARTE SRL | Alessandro Pagliarani – CEO

A long lasting partnership - WM THERMOFORMING MACHINES | Giorgio Zucchi – Sales Area Manager (France & Asia)

Streaming live from WM – Always connected, always with you Live demonstration with FC 1000 IM2 making XPET trays - WM THERMOFORMING MACHINES | Joerg Huth – Sales Area Manager (East Europe)

Guest speaker: KGL | Agata Kaczmarek – Export & Sales Manager

Expanded VS Rigid PET: machine trials and results - WM THERMOFORMING MACHINES | Gregory Romanski – Sales Area Manager (North & South America)

How to improve your overall equipment efficiency (OEE). INDUSTRY 4.0 - WM THERMOFORMING MACHINES | Luca Oliverio – Sales Director

Q&A and Conclusion

Choose your session (Switzerland (CEST) UTC+2)

To register, click on the selected session:

ASK THE EXPERT! Take this chance to engage with the experts and interact with questions. Submit your questions during the livestream event, or by sending an email to sales@wm-thermoforming.com

ABOUT WM THERMOFORMING MACHINES:

WM Thermoforming Machines has been designing and manufacturing reliable high-performance thermoforming and in-line machines since 1981.

Why Choose WM?

- Smart company management: experience underlie the constant improvement of our machines and our service. We believe in the importance of making experiences, pushing our limits, and turning challenges into opportunities to learn, improve and achieve greater accomplishments.

- Ease of use of the machinery for basic users, with an advanced integrated technology available for the skilled operators.

- Long-standing team and deep-rooted technology, resulting in user-friendly, low maintenance equipment.

- Perfect parallelism, symmetric motion, no vibration, no lower platen deflection.

- The PERFECT CUT, supported by an amazing speed and automated stacking system.