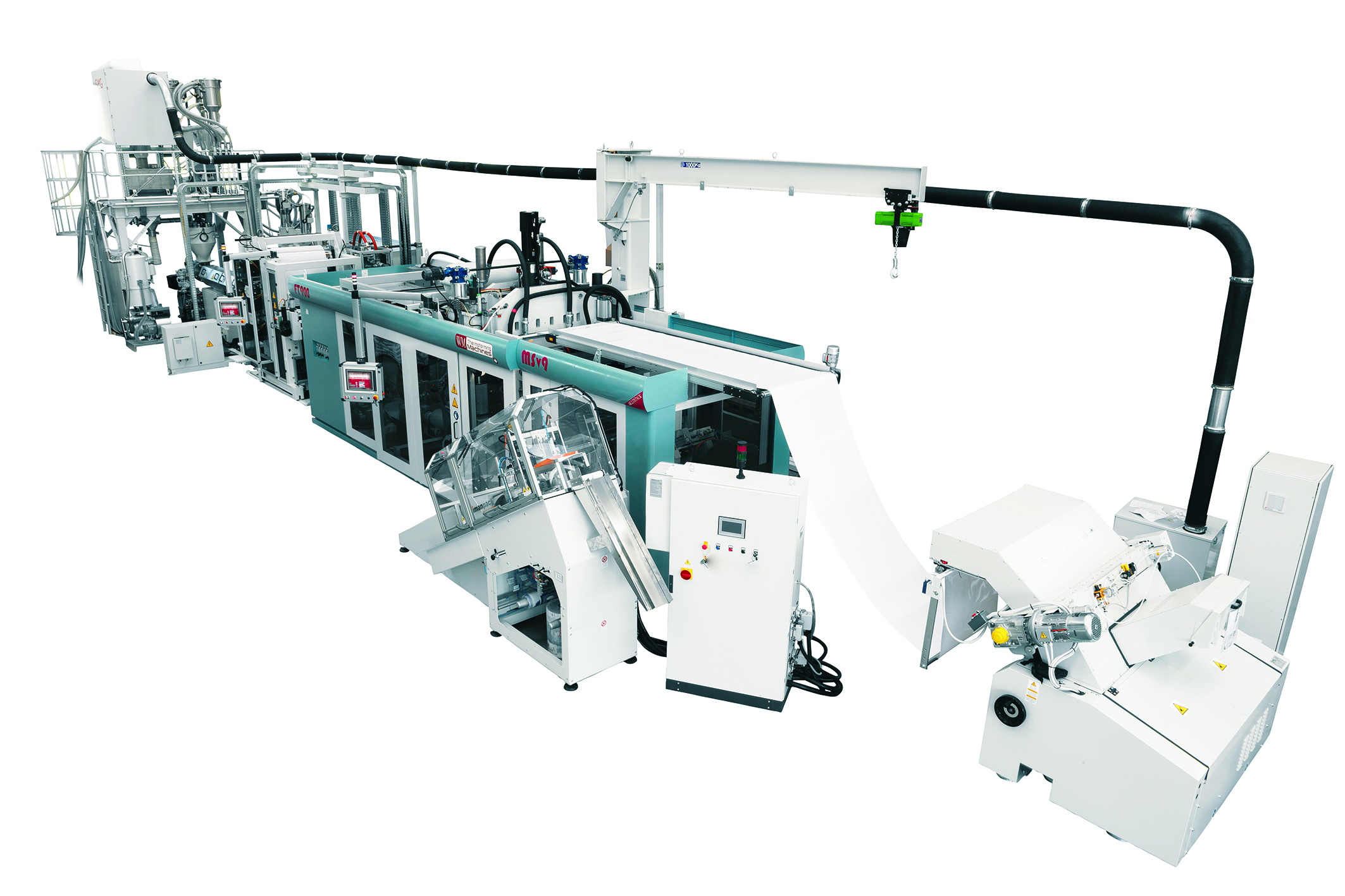

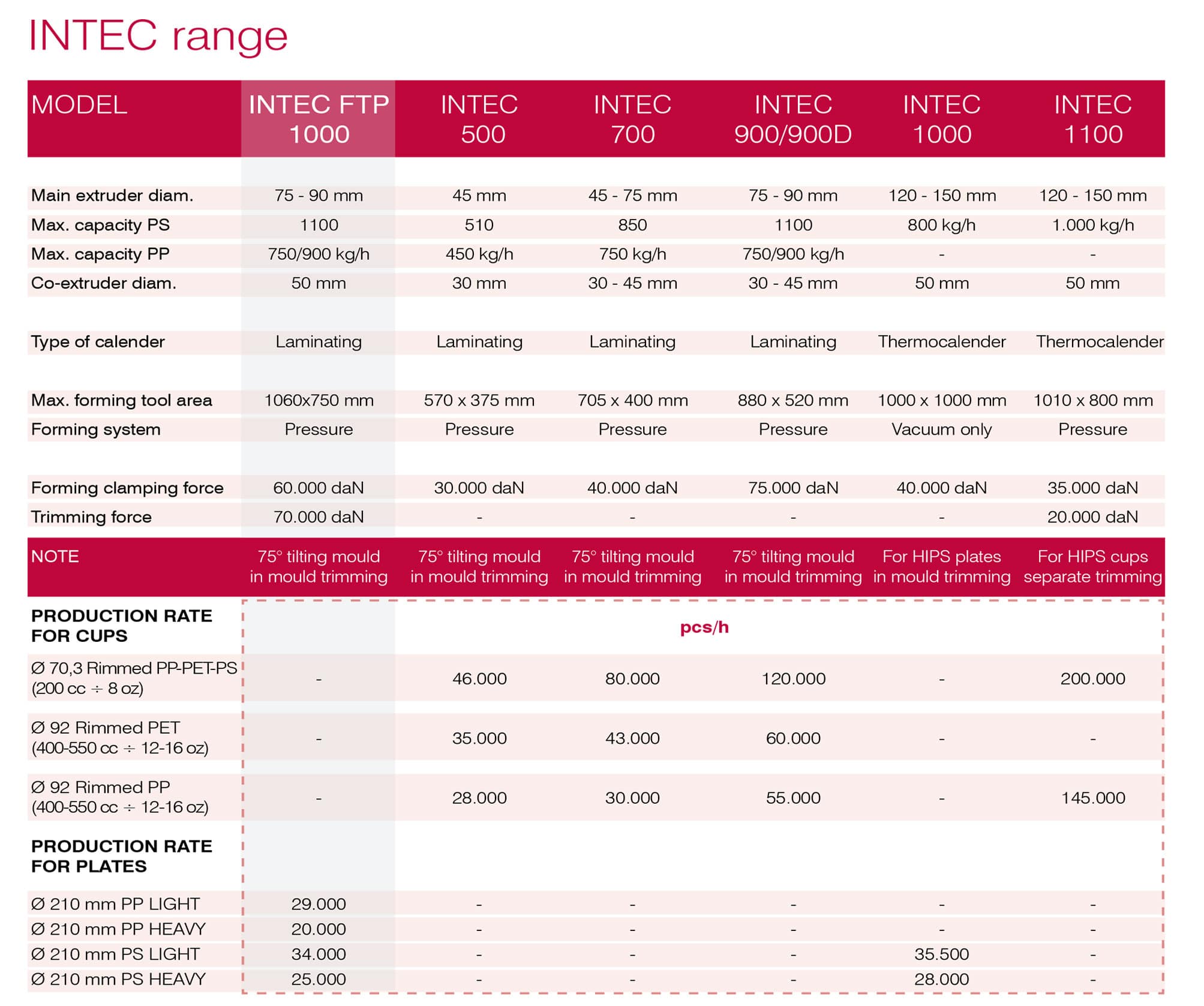

INTEC 500 / 700 / 900 / 900 D / 1000 / 1100

INTEC IN-LINE extrusion and thermoforming plant, the most efficient system to manufacture plastic cups and containers

INTEC offers the following advantages to the end-user versus the off-line system:

- PERFORMANCE – The INTEC is designed for very high output running 24 hours 7 days a week.

- IMPROVED PRODUCT QUALITY – The immediate processing of the extruded sheet into a thermoformed containers allows lower temperatures and better heat distribution during the process and gives the product better clarity, improved mechanical stiffness and better appearance. Furthermore, the instantly scraped recycled scrap prevents contamination of the product.

- LESS USE OF MATERIAL – No edge trim, the skeleton is immediately re-extruded. Possibility to down gauge the sheet keeping the same product stiffness.

- BETTER ENERGY EFFICIENCY – The residual temperature of the extruded sheet reduces the amount of required heating generating an estimated energy saving up to 25% during the entire process.

- OPTIMISATION OF PRODUCTION OUTPUT – The down-time associated with roll changing is eliminated and it is possible to immediately correct any problem arising in the extruded sheet with the minimum of scrap.

- SPACE REDUCTION – There is no need for winding and unwinding the sheet, thus generating important space savings: No intermediate storage area and transportation handling required . In addition, the direct processing of the scrap also reduces the space requirement significantly.

- PERSONNEL REDUCTION – The INTEC line can be managed by a single operator.