Launch of the biggest machine for disposable plates in the market, model IMC-V 100100, delivering 38.000 plates/hour with diameter 220 mm –

- Researches in tilting mould technology lead to the production of the first tilting mould machine IMC-B 540, and later developments with IMC-B 740 reach an interesting productivity of 80.000 PP 200 cc cups / hour.

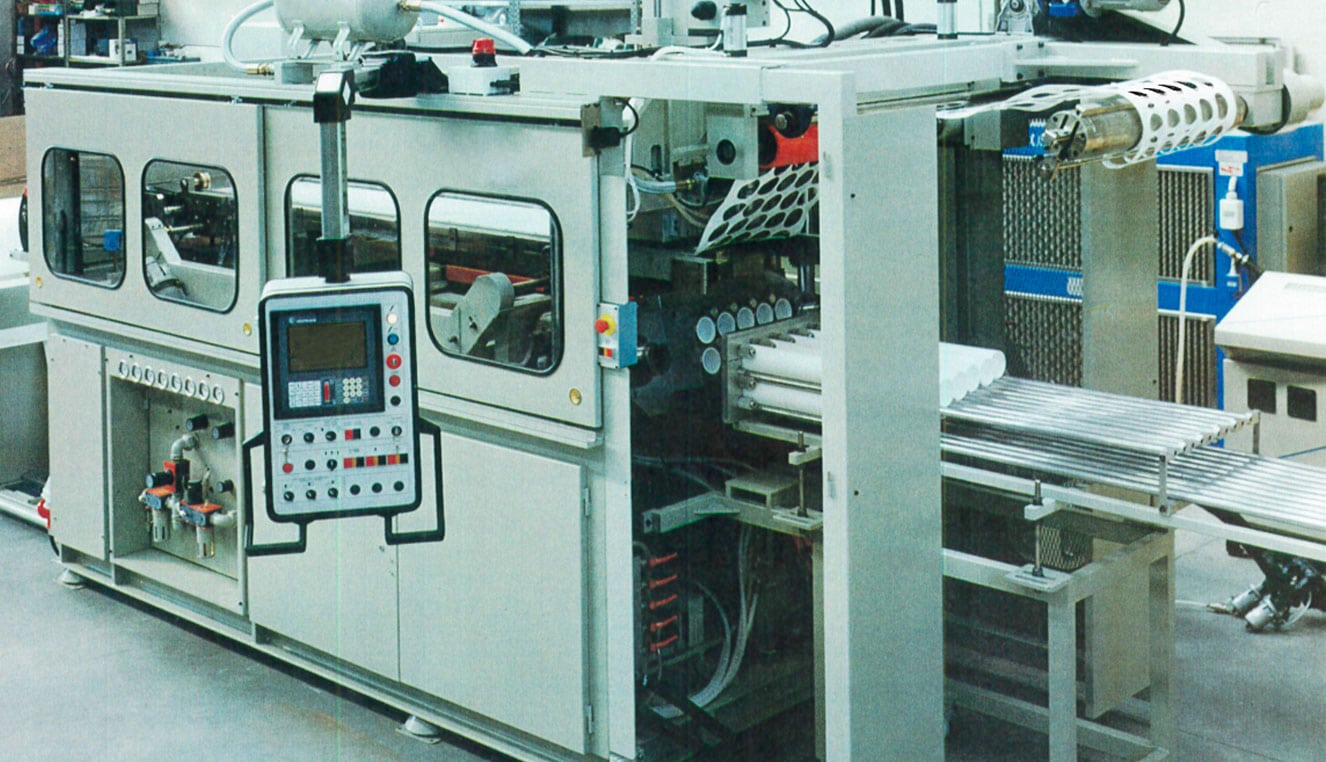

- WM starts manufacturing complete IN-LINE extruders feeding directly the thermoforming plant with the INTEC 800 for disposable cups. Third generation steel rule cutting machine FCS 720 is released, and T-IML (in-mould labeling) system is developed in combination with the tilting mould machine model IMC-B 740.

- Introduction of the first fully electrical machine model FC.