Thermoforming is a process for the transformation of plastic material by heat and combination of compressed air/vacuum and cutting with steel-rule blades.

What is a Thermoforming machine?

Through our thermoforming machines we transform plastic raw material which has previously been extruded into reels of sheet. The sheet thickness is generally up to 1.8 – 2.0 mm, but we can handle thicker product even up to 3.0 mm according to the application.

Thermoforming process: equipment and stages

Thermoforming stages are very important to achieve the PERFECT CUT.

Perfect cut means:

- top product quality;

- longer knife life;

- lower machine clamping force required;

- close cutting tolerance

- less process variation and less adjustement;

- better material utilization;

- faster process;

- zero vibration

These results are achieved by understanding and developing different variables.

As for the machine, we have to consider the rigidity of the system vs the clamping force, the accuracy of the parallelism, and 0 mechanical yoke.

When we look at the tool on the cutting station, we have to consider the steel rule die geometry, the auto centering and the heating of the knife.

When speaking of the material, it is important to have even thickness to ensure stable cutting performances.

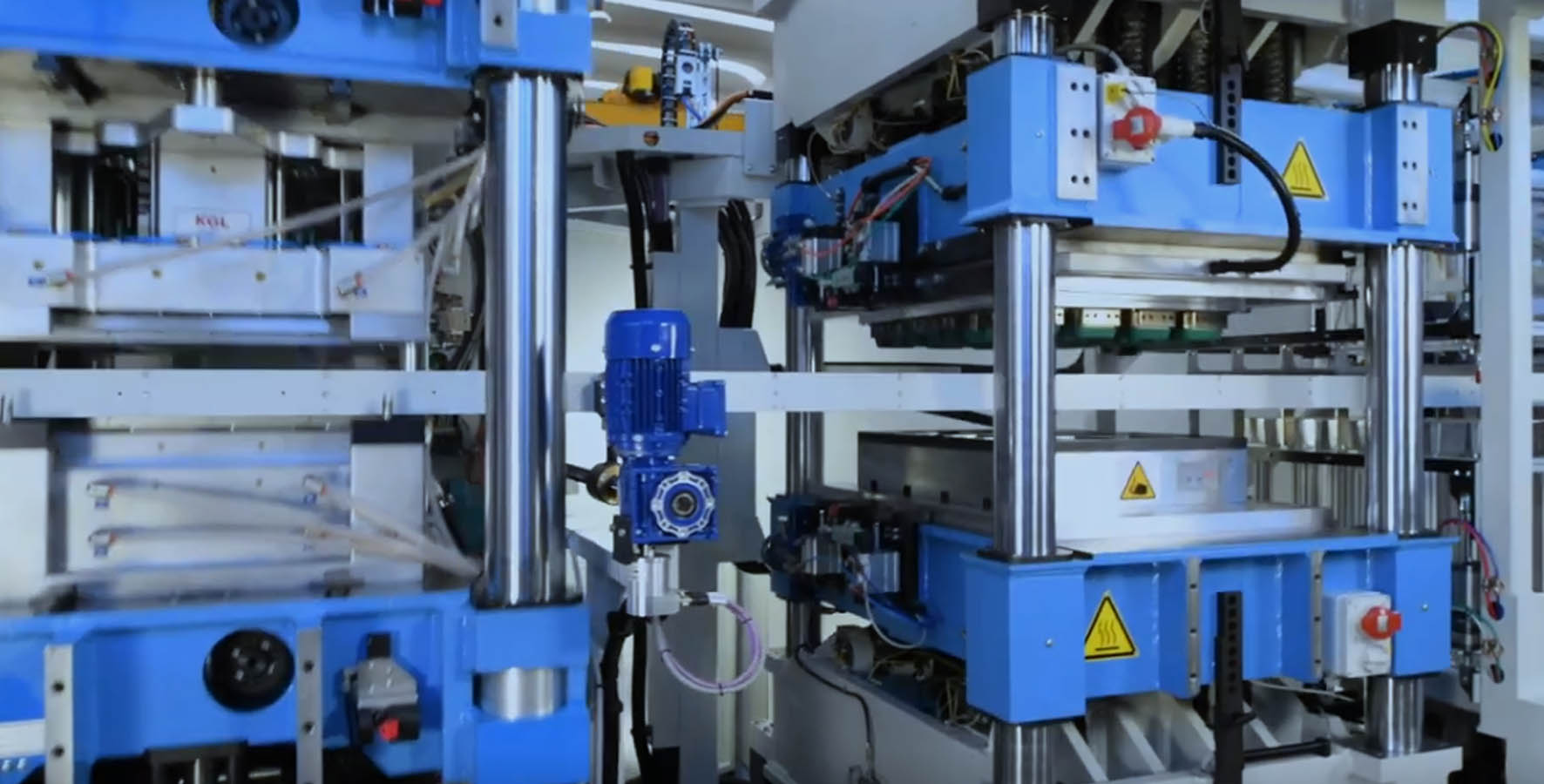

Steel rule die is the heart of the process, and our cutting stations are built with no compromises:

- 4 columns – perfect parallelism – no vibration

- High rigidity K factor (Kr) for columns and platen

- Dynamic and static yoke reset

- Symmetric motion – double toggle system

- Perfect power distribution

- Rationalized acceleration and breaks

The process of thermoforming plastics

The thermoforming automation journey goes through these passages:

- The thermoforming project starts with a design. We need model or drawing of the product, or a sample from the customer.

- The next step is the material. We need to know which plastic material will be used for the project, among the many options available. It is important to choose the most suitable material possible: it has to maintain its characteristic during the extrusion, to avoid invonveniences during the thermoforming (for example, adjusting the parameters more frequently to overcome the variables, and so on). For this step we offer the full support and expertise of our team to our customers, to help them in the decision process.

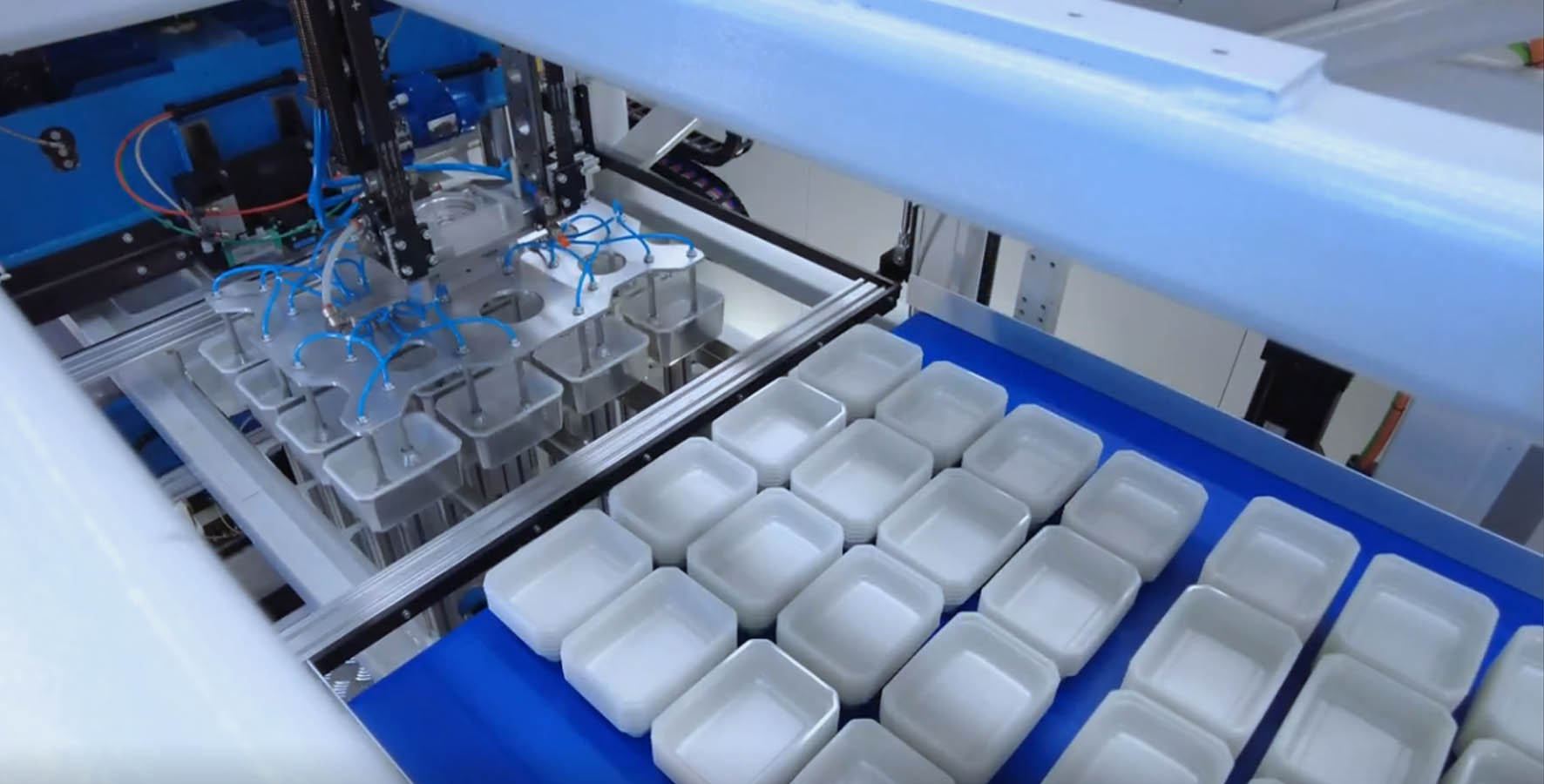

- The next step is tooling. In the thermoforming machining process this part is the manufacturing of the mold to heat the plastic. With the information about the product and the material we can estimate the number of cavities of the mould, and expected cycle time. With these data, the mould maker has all the details to build the tooling accordingly.

- The next step is to form the plastic into the mold. There is a first heating to soften the plastic sheet. By means of vacuum pressure, air pressure or a combination of both, the material is shaped in the mould and becomes a product. Once the material has reached its final shape, it’s cooled and removed from the mold.

- Products are carried to the final station (the stacker), where they are removed from the skeleton and stacked.

Follow us:

Linkedin https://www.linkedin.com/company/wm-thermoforming-machines-sa

Youtube https://www.youtube.com/c/WMThermoformingMachines