WM Thermoforming Machines will attend CHINAPLAS in Shanghai from April 24th to 27th 2018 in the Swiss Pavilion, Booth: 2D-31. WM Thermoforming Machines is ready to show at CHINAPLAS the rebel machine that is breaking thermoforming limits in smooth running, the latest technological innovation on punch and die tilting mold technology called TWIST 700.

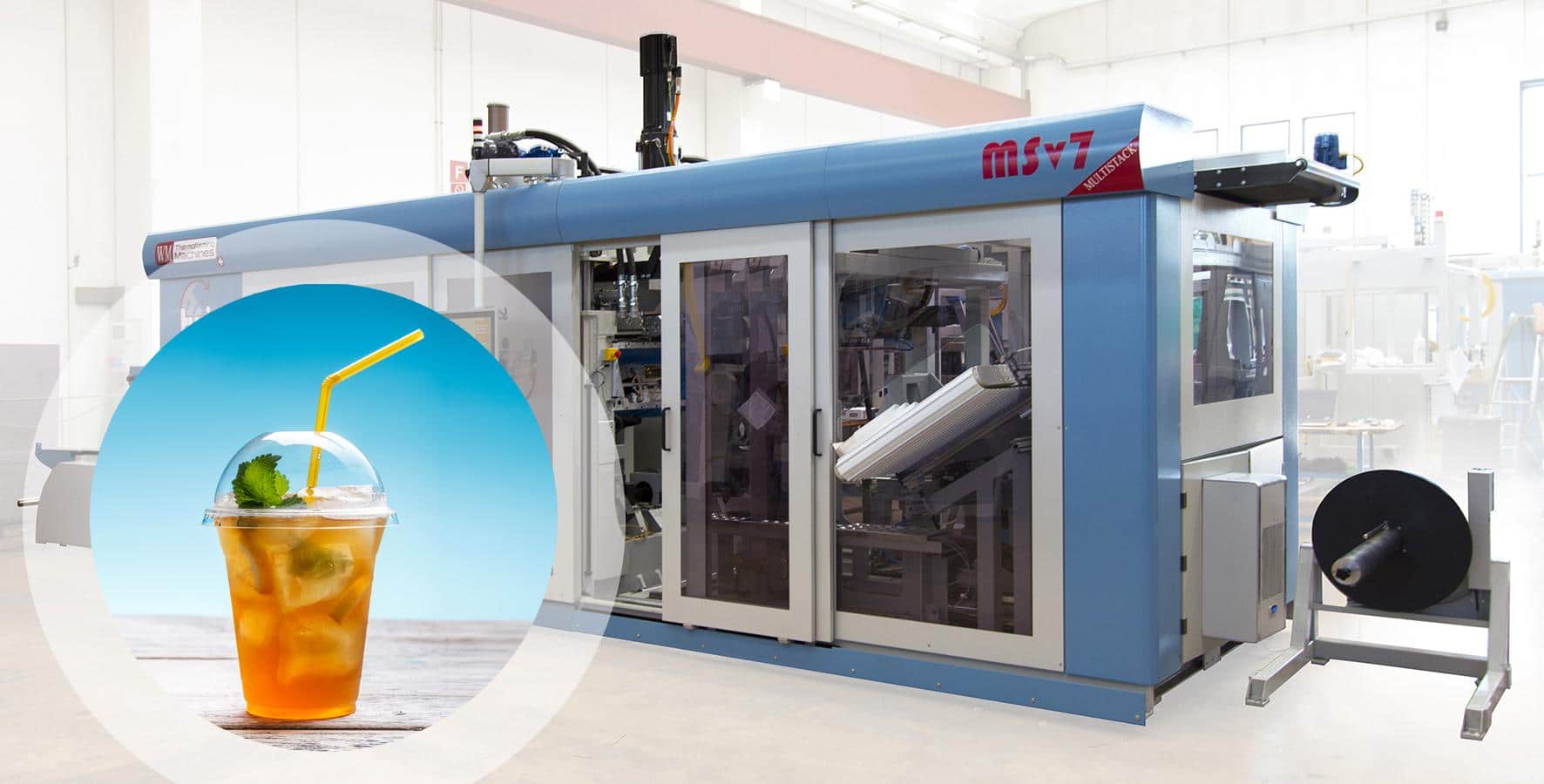

The TWIST 700 running at CHINAPLAS is a high-speed machine with 18 cavities, thermoforming 24 Oz cups from 1.7 mm PET rolls, supported by the elegant and precise stacker model MSv 7, fully synchronized and supervised by WM Machine Learning System (MSL).

The MLS system consists of two packages, allowing the user to have a full control of the operations:

- MAS – Multi-Axis Synchronization in motion control is giving to the operator the possibility to set machine speed and stroke easily just by inputting few parameters. MAS system is using these parameters to synchronize machine and stacking motions without operator overview, to guarantee the perfect power control.

- TPM – Thermoforming Process Monitoring stores and displays to the operator, cycle by cycle, the most important process parameters in order to compare the optimal parameters with the on-running effective parameters.

In addition, TWIST 700 has more features that make it the ideal machine for the leading companies in food packaging industries.

- The lower tilting platen, moved without mechanical cams, rotates 75° and is guided on prismatic linear guides to reduce vibrations.

- The electronic cam guarantees an absolute precision and repeatability of the movements.

- The new camless motion system reaches up to 50 cycles/minute in production, guaranteeing efficiency and speed.

- The upper and lower platens have an interface designed to receive most of the existing tools.

- The higher clamping force insures more cavities for PET and PP material.

- The Universal stacker enables easy automatic handling of light and shallow products to the packaging machine. As the stacking system does not use any brushes or rubber material, the production is more hygienic.

- The integrated cooling system with temperature monitoring insures a stable and safer process.

- Overall, the TWIST 700 ensures an easy operating and maintenance.

- Full synchronization and total process control makes the Twist 700 the best choice to match high speed with top quality, a human ambition made real!

Professional competence and experience cannot be improvised as they are the result of continuous research, constant growth and development. Our solid and deep roots contribute greatly in shaping our future, but our customers are the ones who really push us one step ahead.

“Some people want it to happen, some wish it would happen, WM Thermoforming Machines makes it happen”

Our Area Manager, Mr. Andrea Crespi, will update customers about all the recent innovations regarding the TWIST 700 and the complete range of thermoforming machines and equipment by WM.