WM Thermoforming Machines, the Swiss company based in Stabio, achieved a prestigious goal at the end of July: the delivery of the 110th IN-LINE plant system for extrusion and thermoforming, model INTEC 900/3, for the production of two colors PP cups, to a customer in North America.

And July 2016 will be definitely remembered in the story of WM also for another success, a new record in the sales volume.

But WM prefers to talk of another “brick” that has been added to the growth of the company, established in 1983.

A solid family owned company on its third generation, which can rely on a loyal and growing work force, a company committed to the preservation of high quality standards, to the improvement of its after-sales service, but most of all to the continuous research and development in the field of thermoforming technologies and packaging.

To confirm this, there is the evolution of the vacuum pressure forming machines with steel rule cutting blades, model FC 600/780/1000 integrated with 2 and 3 axes robot, projected and realized by WM, which have reached the third generation, as a result of the studies to increase speed and precision in the stacking.

A very good answer from the market arrived also from the model FC 780 IM and FC 1000 IM that allow in-mould forming and cutting, guaranteeing great precision and high productivity, thanks to the cutting presses with clamping force up to 130 Ton.

The same effort has been put in the punch and die thermoforming machines with tilting mould, model FT 500/700/900 completed by the two new stacking systems projected as an answer to the different market requests.

- The model ES7 (Easystack) has been developed for the customers who have the need of frequently change the mould and it promise low investment costs in the stacking tools and fast mould changes.

- The model MSv (Multistack) allows the stacking of both containers than lids, assuring a precise stacking and unloading on the packaging lines.

Moreover the version D of the FT 900 is ready to be put on the market, the spearhead of the FT series. The FT 900 D version has been rationalized to produce cups and containers in PP by using a sheet thickness of more than 2 mm.

Improvements also on the IN-LINE plants, which has been implemented with the new high efficiency and low consumption extruders model N.EXT 30, 45, 75 and 90 mm that can produce up to 900 Kg/h of PP.

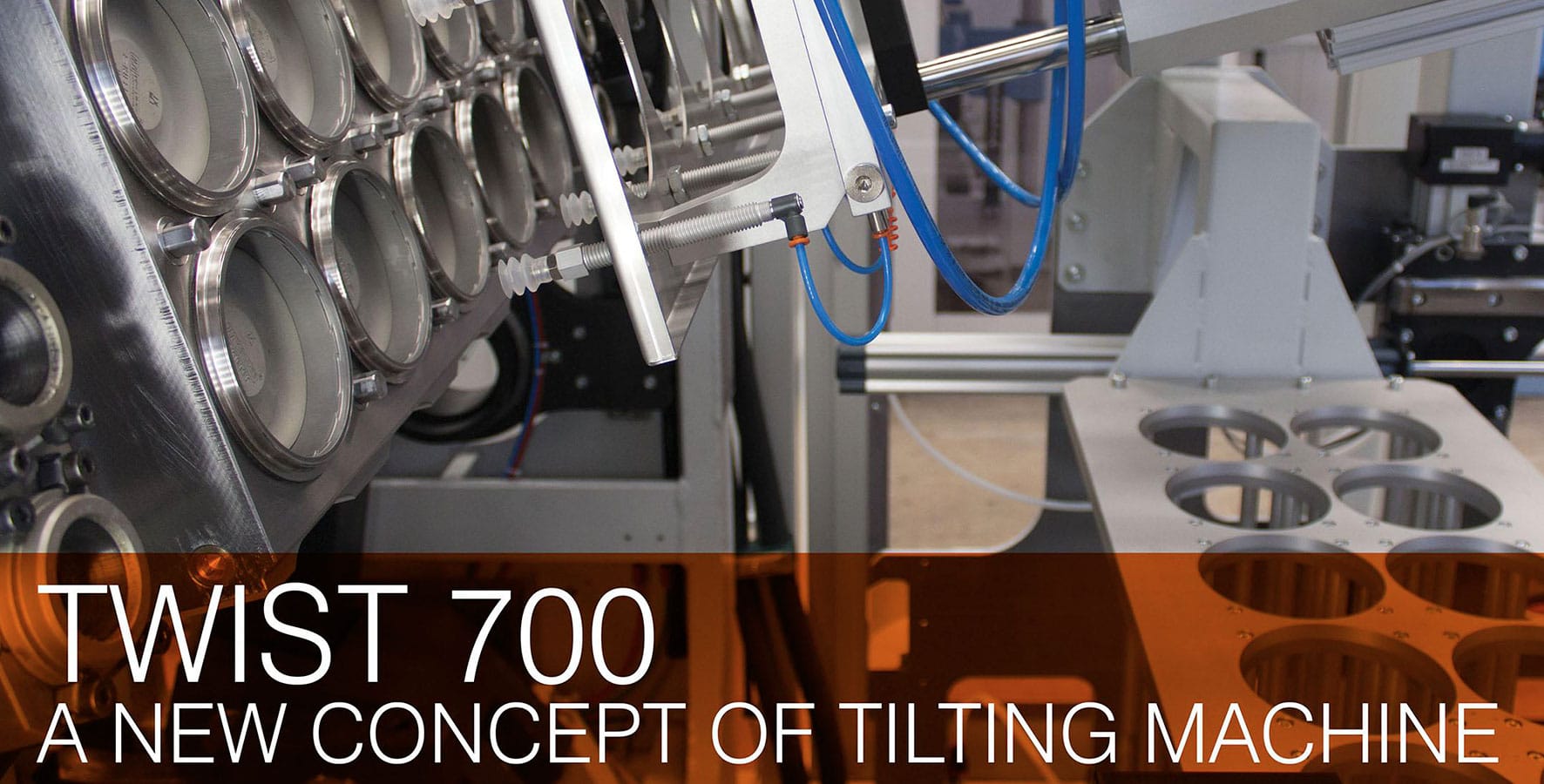

And if that’s not enough, WM following the spirit of continuous innovation, for those who are even more curious about technology will reveal at K show from 19-26 October a newly designed thermoforming machine with tilting platen: the model TWIST 700, born to produce containers in PP, PP/EVOH and PET that requires very high qualitative standards and narrow dimensional tolerances.

The visitors can find more details about the features of this new machine at Hall 3 Booth A16, where it will be the moment to meet, in a friendly atmosphere, new and well-established customers interested to the excellence of thermoforming.

Obviously on the booth there will also be video and documentation about the whole WM’s thermoforming machines range and IN-LINE plants, leitmotiv the theme of the advertising campaign “Nature-like protection”, represented by a chestnut enclosed in its urchin. The urchin protect its fruit, just like the plastic packaging protects the products contained.

But WM is looking forward. We circle back to where we started, in the period before and after K Show in WM headquarter it will be possible to see a working IN-LINE extrusion and thermoforming plant for the production of PP cups. While, for those who might be interested in an IN-LINE plant with co-extrusion, the appointment is on December 2016 with the a new INTEC FT 900/3 for PP and PS.