The available wide range of thermoforming machines for in mold punching with lower tilting platen designed and manufactured in Switzerland by WM Thermoforming Machines SA represents the first class state of the art answer to the market requirements of high quality economical batch sizes such as cups, bowls and tubs.

This well proven and unbeaten reliable technology of the tilting group uses a combination of servomotor driven cams and levers, based on an innovative Double Desmodromic System which guarantees less vibrations compared to the other existing solutions available on the market.

The absolute precision and repeatability of movements assures high quality products and long live to the punches and the tools of the mold. Three different sizes are available: FT 500 (570x375mm.), FT 700 (705×400 mm.) and FT 900 (880×520 mm.) offering the most suitable solution to the small, medium or large production batches.

All models are equipped with a specific assisting-plug system where the plugs movement is controlled by dedicated servomotor providing an even and controlled distribution of the material inside the mold cavities. The possibility to set and program the different plug speeds and times can considerably improve the aesthetic appearance of the final products especially when using transparent materials.

Great attention is paid in terms of real energy saving, assured by IPG system (Integrated Power Regeneration): the kinetic energy is converted in electrical energy that is regenerated into the power system of the machine. All FT series models are equipped with a latest generation software technology for a perfect management of all the cycle parameters and machine functions. The operator is guided in a very simple and safe step by step setting and all recipes are recorded on a USB with no limitations.

The controls system is based on an extremely proven and reliable, well tested B&R industrial PC combined with a compact device touch screen. ETHERNET switches are included to connect the line to the Company network, as well as the RSA (Remote Service Assistance), a new access hardware support, an evolution of the modem connection, with the advantage of higher speed without phone connection costs for a very efficient and precise after-sale service all over the world.

A very wide range of stacking devices are also available, specifically studied for all particular production needs: from the most simple and economical ES (Easystack), up to the stacking and transfer unit with rotating plates RS (Rotostack), passing through other solutions for very shallow and thin products MS (Multistack). These stacking and counting units enable single-lane feed to downstream equipment like rim-rollers and packaging group.

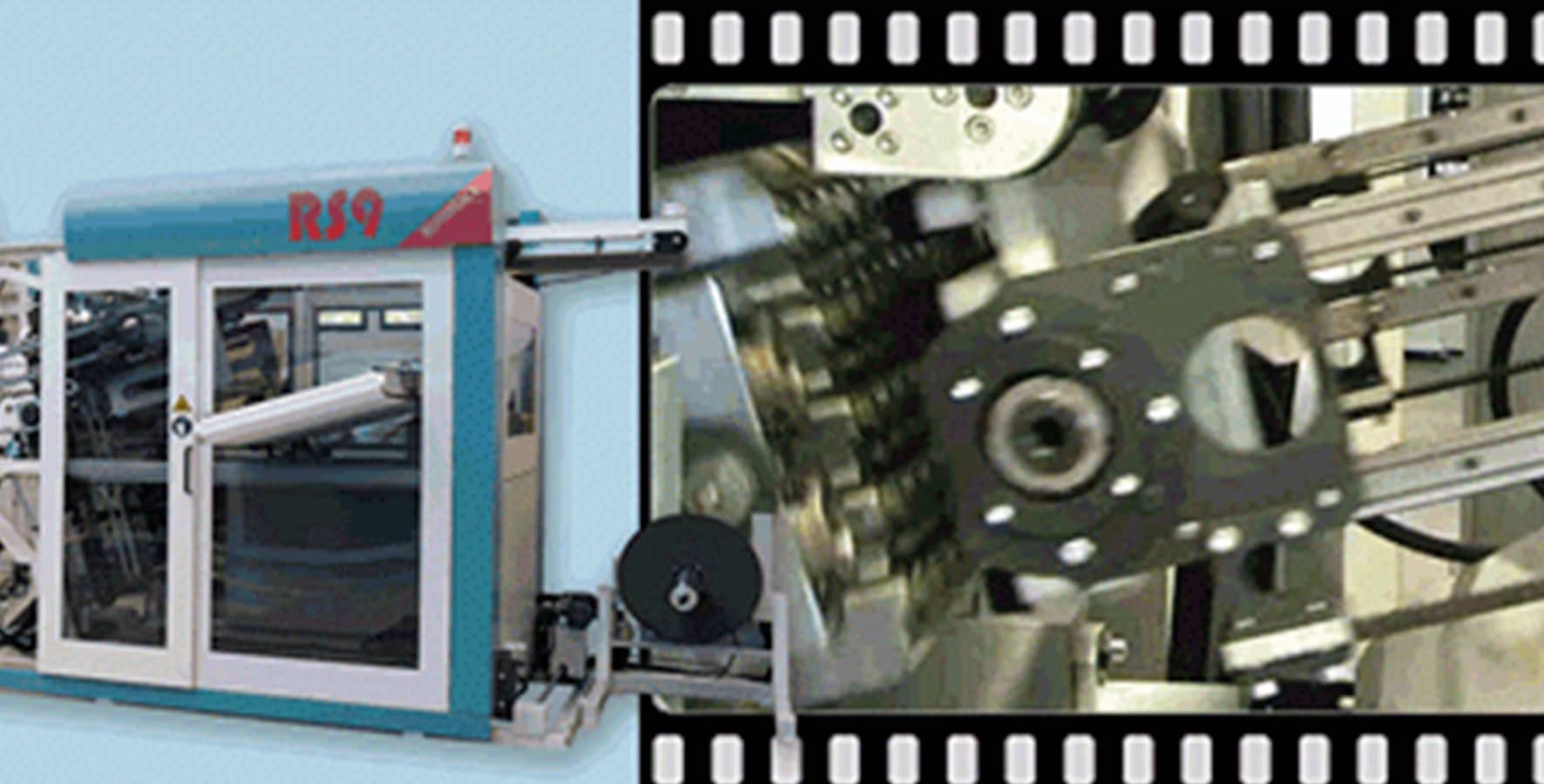

Recently WM supplied a machine model FT 500 (570×375 mm.) for the production of PP multilayer coffee pods with a 40 cavities mold (see the pictures) equipped with a RS (Rotostack) unit.