WM Thermoforming Machines SA has realized and supplied the first complete INTEC thermoforming In-line plant in February 1993.

Since then, more than one hundred complete In-line plants have been supplied and are now operative all around the world.

The main countries where these In-line systems are installed are Italy, Spain, United Kingdom, France, Turkey, Israel, Saudi Arabia, Indonesia, Brazil and Australia.

Final users of the Intec lines are manufacturers of disposable plates and cups as well as of the so-called “aquacup” containers and the most used materials are High Impact Polystyrene (HIPS) and Polypropylene (PP).

Some of the plants have been designed for multilayer sheet, used for the production of items in HIPS and for PP cups; WM also finalized a line composed of 4 extrusion groups for the production of two-colors cups.

General functioning of the In-line system:

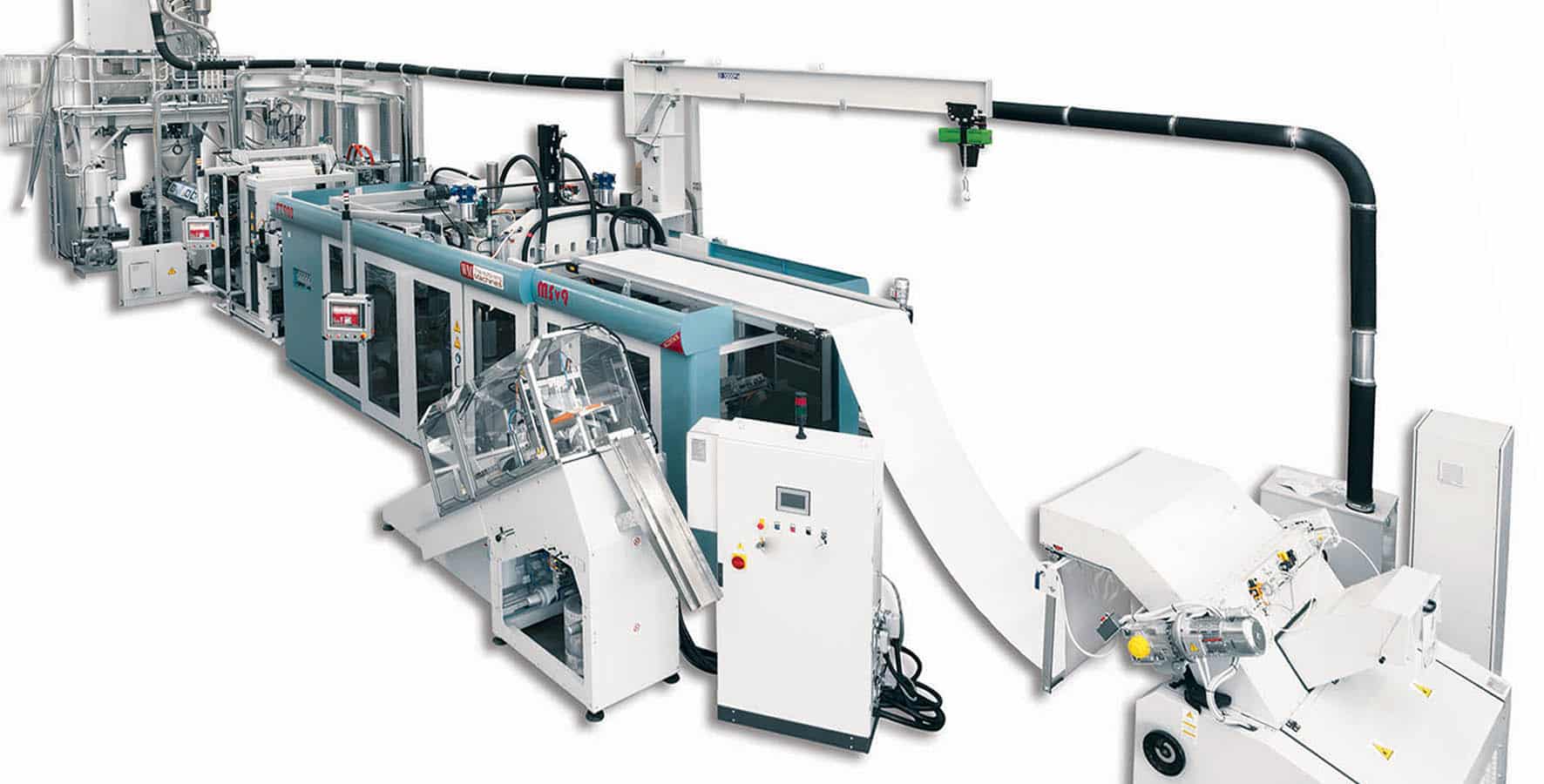

“In-line thermoforming” means a “closed loop process”; a complete “turnkey installation” which starts from the handling of the raw material granules and arrives to the boxing of the finished products.

The line begins with the sheet extrusion group which may be equipped with one or more extruders, depending on the quality of the sheet needed (mono or multi-layer).

In the extruder hoppers the required proportion of granules of virgin material and granulated scrap, returning from the line itself, are dosed and mixed before feeding the extruders.

Single screw extruders mix and plasticize the materials and a compensation gear pump guarantees a constant feed to the flat extrusion die head.

The flat die controls the characteristics and the thickness of the extruded sheet which is fed into a temperature controlled calender.

The calender

There are two different types of calender available depending on the material used:

- Laminating calender: consists of three rolls that provide to the thickness calibration and the cooling of the sheet itself, then a haul-off unit feeds the transport toothed chains of the thermoforming machine where the sheet is re-heated by an oven consisting of upper and lower heater banks with infrared heating elements. This kind of calender may be used either for HIPS and PP.

- Thermocalender: consisting of five coated rolls used to maintain the temperature of the extruded sheet, that is fed directly to the thermoforming machine where the material is thermoformed without passing in the oven because no re-heating is required. The thermocalender is normally used for HIPS only.

After the calendering phase, depending on the nature of the final product, the thermoforming machine may be equipped with:

- Forming and punching in place (cutting of the perimeter of the product directly into the forming tool) in a single station; or

- Forming and subsequent separate trimming (the cutting of the product edges is made after the forming into a separate press) two different stations.

The products are then stacked, counted and sent to the packaging groups, while the line scraps are fed to a granulator. The re-grinded material is finally blown back to the dosing-mixing units over the extruders to be reprocessed.

Efficient, hygienic and economical. An intelligent way to increase the output and reduce production costs.

Advantages of the INTEC in-line thermoforming process:

- Improved quality of the final product.

Thanks to the immediate forming of the extruded sheet, the characteristics of the foil are regular and constantly under control. This enables, during the forming phase, the improvement of the mechanical structural properties and of the aesthetic appearance of the final product.

- Better use of raw material.

Lighter shapes with the same rigidity. In many cases it is possible to reduce the thickness of the sheet (and the final product weight) thanks to the fact that the heart of the sheet is warmer and a better plug stretching assures a more accurate material distribution into the mould cavities.

Furthermore, the immediate recycling of the scrap, without handling or storage operations, prevents the contamination of the material and leads to improved quality and hygienic condition of the final product.

- Better use of energy = energy saving.

The residual temperature of the extruded sheet reduces the heat quantity normally required in the forming phase.

- Space reduction.

With the In-line extruder, the winding of the sheet into rolls is completely eliminated, saving all the handling time and storage space.

The compactness of the line, the elimination of rolls storage room, the direct reprocessing of the scrap, result in a marked reduction of space and costs.

- Personnel reduction.

The complete line can be managed by one operator only. The high level of the line management, based on an extremely reliable and well tested B&R industrial PC, makes the operator’s job easier.

- Optimization of production output.

No down-time for rolls changing.

Eventual quality problems arising from the extruded sheet can be quick detected and resolved, reducing scrap at minimum.

More efficient = more economical.

Working In-line: facts to consider

The In-line process is usitable for huge and long series productions. Disposables plates and cups, dairy products containers like yogurt cups or butter/margarine tubs are typical applications.

Due to the involvement of extruders, calender, thermoforming and stacking groups, it takes time to change from one product to another.

The In-line process requires one extruder for one thermoforming machine. For this reason in some cases the In-line thermoforming doesn’t offer the same final Kgs output than using one extruder separately. It is important to size properly the extruder capacity according to the product to be thermoformed.

—> WATCH THE FULL SYSTEM HERE: https://www.youtube.com/watch?v=WdJZ3rGff2k

Conclusion:

The production with In-line technology system has extremely positive results in terms of quality, costs and efficiency, despite a little less flexibility. For large batches the investment in the In-line solution is absolutely convenient.

Want more information about this system?

Contact us on:

sales@wm-thermoforming.com for any questions or further information.

subscribe to our newsletter to follow our updates

follow us on Youtube or Linkedin