The correct and constant control of the temperature of the heating ovens is an important and often critical factor to obtain a quality final product.

In order to improve the correct regulation of this parameter, WM proposes two systems of control. The first acts on the temperature of the heating ovens according to the changes in the room-temperature of the working environment; the other corrects the regulation of the ovens temperature on the base of the temperature of the sheet.

- The measurement of the room-temperature: this device is present by default on all WM thermoforming machines models. It allows to keep constant the ideal temperature setting of the ovens, once identified by the operator, regardless of the temperature changes in the working environment.

For example, if for a temporary opening of a door in the production plant the room-temperature decrease, the control device in the machine will automatically compensate the thermic shock by increasing the temperature of the ovens in order to restore the optimal condition of work.

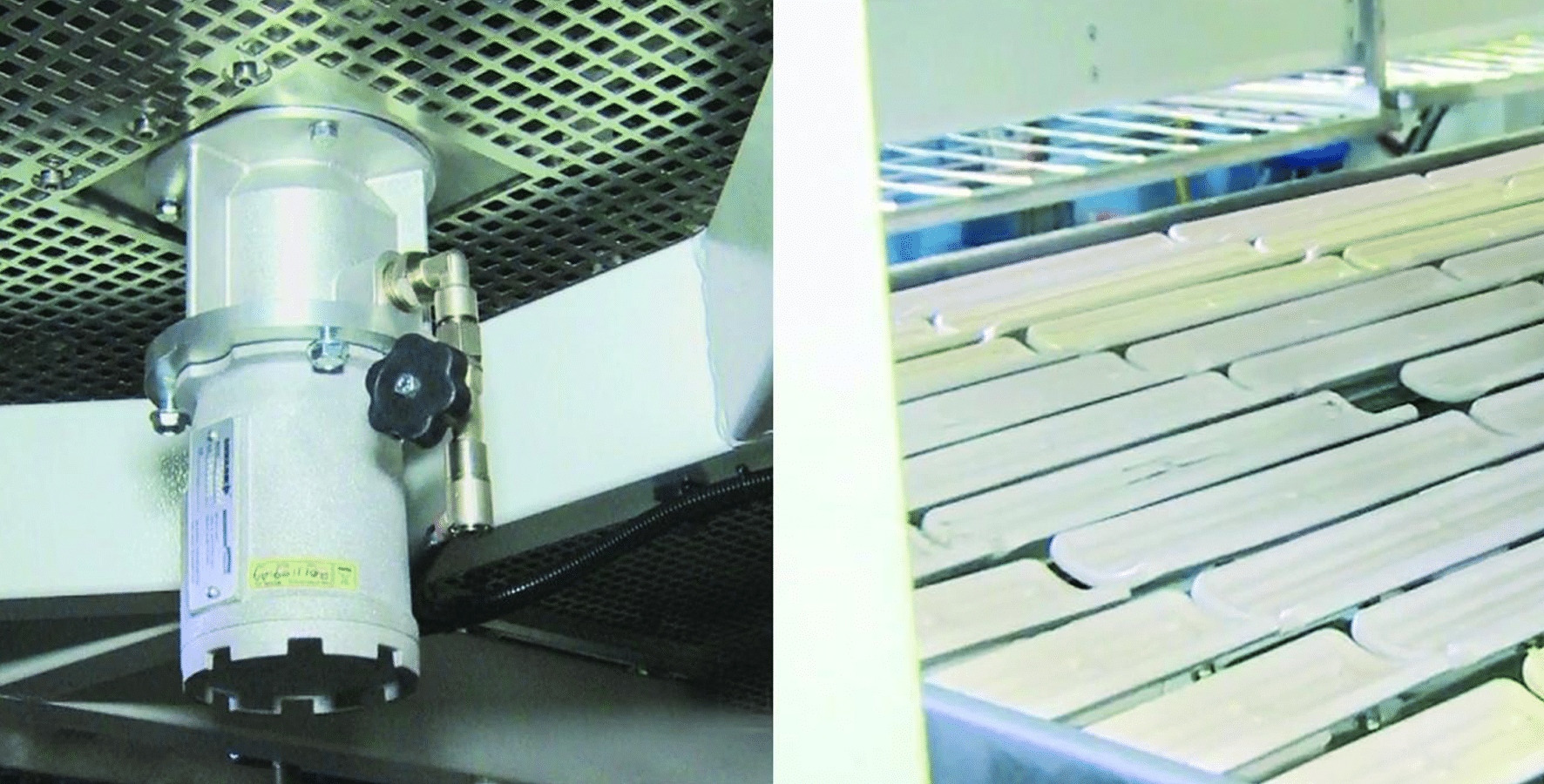

- Measurement of the sheet temperature: this is an optional device which includes a digital pyrometer installed in the part closest to the mold in the bottom heating oven. This pyrometer reads the temperature of the sheet and if it register an abnormal datum, operates on the heating parameters by increasing or reducing them until the temperature of the sheet is not restored to the ideal values determined by the operator.

There is no more need of intervention by the operator for the manual setting of the temperature inside the ovens, even if the temperature difference is due to external factors in the general work conditions.

This automated control system ensure, therefore, the stability of the heating temperature of the sheet even in case of change of speed of the machine cycle. If, for example, the cycle of the machine is accelerated and the material stays a shorter time in the oven, the system will automatically increase the set temperature. On the contrary, in the case of a speed reduction, the system will provide the decrease in the set temperature.

It’s also possible, during the production cycle, verify the constancy of the temperature of the sheet in a certain period of time, through a specific chart that can be also printed on paper to be used as standard reference.