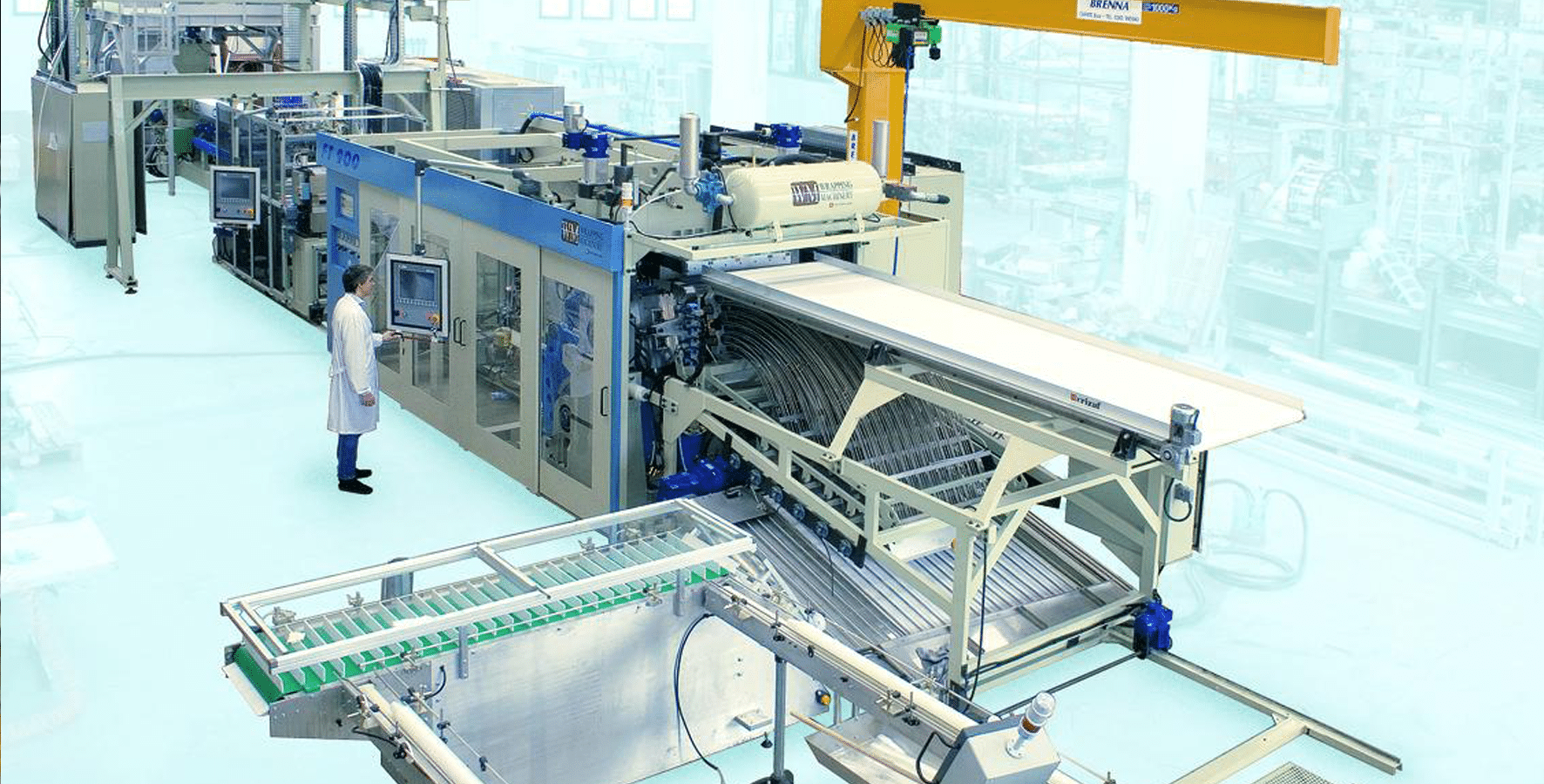

INTEC FT 900 IN-LINE thermoforming plant for PP disposable cups. At the end of February a complete in line plant for the production of polypropylene cups has been delivered to France.

The line includes dosing/feeding group, 120mm single screw extruder, thermoforming machine FT 900 with lower tilting platen, stacker, in line rimming unit and scrap grinder.

The pressure forming machine FT 900, (880 x 520 mm) was equipped with a 57 cavities mould.

The weight of the rim rolled cup is of 2,5 gr. and the line cycle is 34/minute for a total production rate of more than 120.000 cups per hour.

WM Wrapping Machinery Sa is specialized in the in line production of plants for disposable plates and cups, either for polystyrene or polypropylene and more than one hundred of this lines have been supplied all over the world.

The production of polypropylene cups has significantly grown up in the last years and the in line plant represents the ideal solution for high output with the lowest material consumption, reduced energy, minimum labour requirements and best utilization of space.

Due to the immediate thermoforming of the extruded sheet, the characteristics of the sheet are uniform. Furthermore, the immediate recycling of the scrap prevents contamination and leads to improved quality of the final product.

The production time reduction associated with material rolls changing is eliminated and there is the ability to immediately correct any problem arising in the extruded sheet with the minimum of scrap.

With the in line extruder, the winding of the sheet to rolls is eliminated, saving all the handling time and storage requirements.

The compactness of the line and the direct reprocessing of the scrap give a marked reduction in the space required.

Finally, the complete line can be managed by a single operator.

All the mentioned advantages may be summarized in simple words: more efficiency = more economical.