WM Wrapping Machinery SA has recently supplied to an important Customer in Indonesia a complete in-line thermoforming plant for the production of PP cups. The in-line plant starts from the material handling through to extrusion, thermoforming, counting and stacking the final product, working with a 54 cavities mould and 32cycles per minute.

The polypropylene cup’s weight is 3.2 gr.

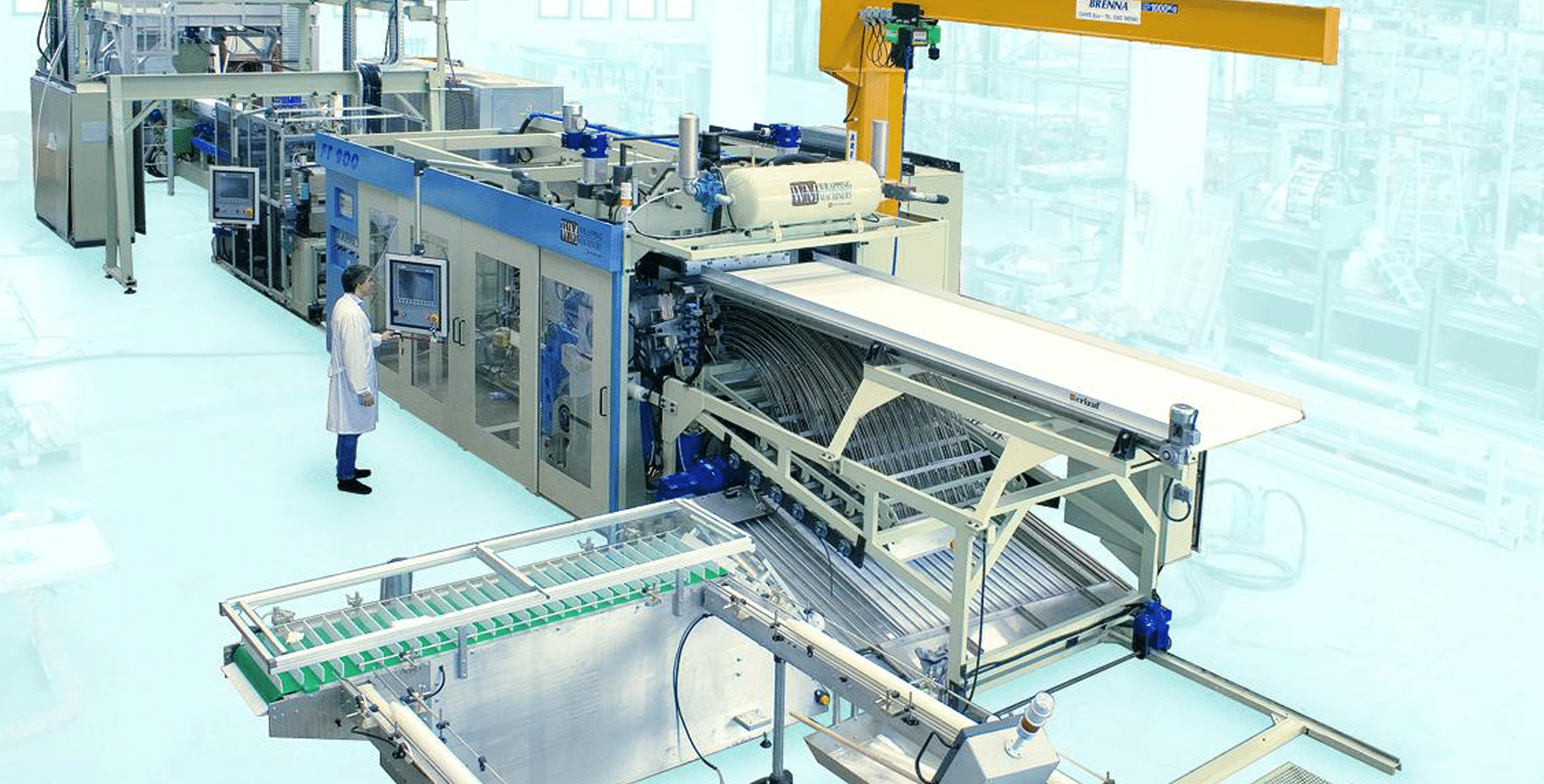

The INTEC 900 (the commercial name of the line) manufactured by our Company is part of a complete range which includes extruders of various sizes and different models of thermoforming machines, in order to meet specific Customers requirements.

A single screw extruder, at the beginning of the line, provides the PP sheet through a vertical laminating calender for a max output of 650 kgs/per hour.

The forming unit is form and trim in place model (FT 900) and the lower moving platen is rotating of 75 degrees to facilitate ejection and stacking of the formed parts.

Very interesting is the stacking group, which consists of a rotating plate, operated by servomotor, which picks up the cups from the mould cavities and push them into proper stacking frames for counting operation and subsequent evacuation on a conveyor belt, in separate piles, ready to be packed.

WM Wrapping Machinery SA has already supplied more than a hundred inline plants all around the world, either for PP and HIPS materials as well as for coextruded sheet.